Electric Heating Tube

- Cartridge Heater

- Finned Tubular

- Immersion Flange Heater

- Heater-Teflon

- Tubular Heater

- Flexible Heater

-

-

-

All products are using SUS304 or SUS321 seamless stainless steel pipe, MOG holder and MGO head with high temperature 1800C,99% MGO rod,overseas high temperature MGO powder, Cr20Ni80 resistance wire ,Ni-Mn lead wire and Silicone Rubber wire .It suits for mold heating . Large-scele production with competitive price,Good-look appearance of the product and excellent quality .

Features of Cartridge Heater:

-

-

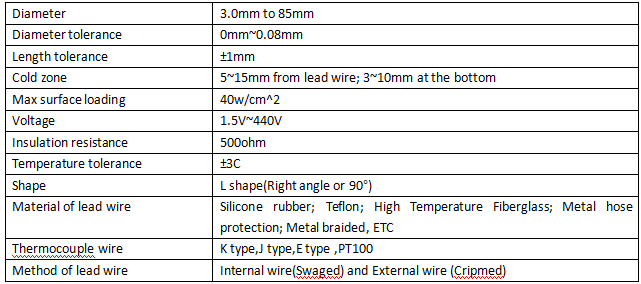

Characteristics VS Properties :

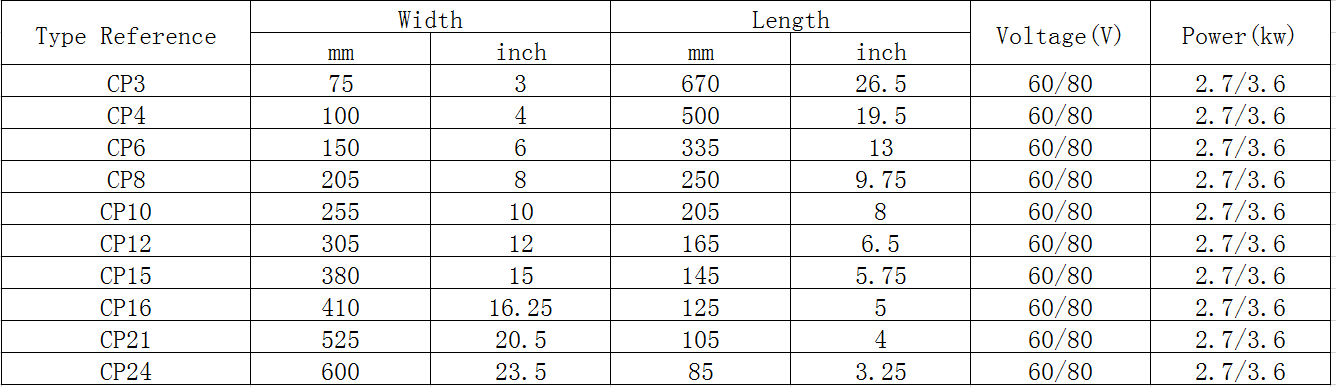

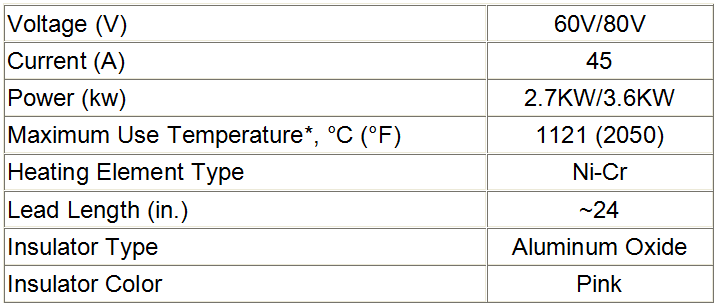

These flexible ceramic pad heaters are designed for most preheat and post heat treatment (stress relieving) requirements on weld joined materials. They can be used to construct a simple, inexpensive furnace when combined with the proper insulation as well as in many other applications where a flexible heater is required.

These flexible ceramic pad heaters are designed for most preheat and post heat treatment (stress relieving) requirements on weld joined materials. They can be used to construct a simple, inexpensive furnace when combined with the proper insulation as well as in many other applications where a flexible heater is required.

Flexible Heater Type is a pad heater constructed of interlocking sintered alumina ceramic beads which insulate stranded nickel-chrome wire. This durable construction forms a flexible mat of considerable mechanical strength. They can be used up to 2050°F (1121°C) and are supplied with insulated leads with male welder terminations.

Information

- Screw/Threaded

- Stainless steel chip

- Fin

- Flange

- Elbow

Which fittings can on Right angle type Cartridge Heater ?

1.We make high quality cartridge heaters according to clients’ sample or drawing ;

2.We can make the most hard products according to clients’ drawings,the max surface load can be 40w/cm2

3.We can design the mold hole diameter hole distance, heating power etc according to clients’ mold and make the high quality cartridge heaters and customers’ mold .

4.Solve the heating imbalance problem specially for big mold,circle-roller and long packing cutter. We can make the cartridge heaters for these products which temperature tolerance within +/-3C.

5.Improve cartridge heater uselife by optimization design and reduce the energy consumption .

Laiyuan advantage of Cartridge Heater:

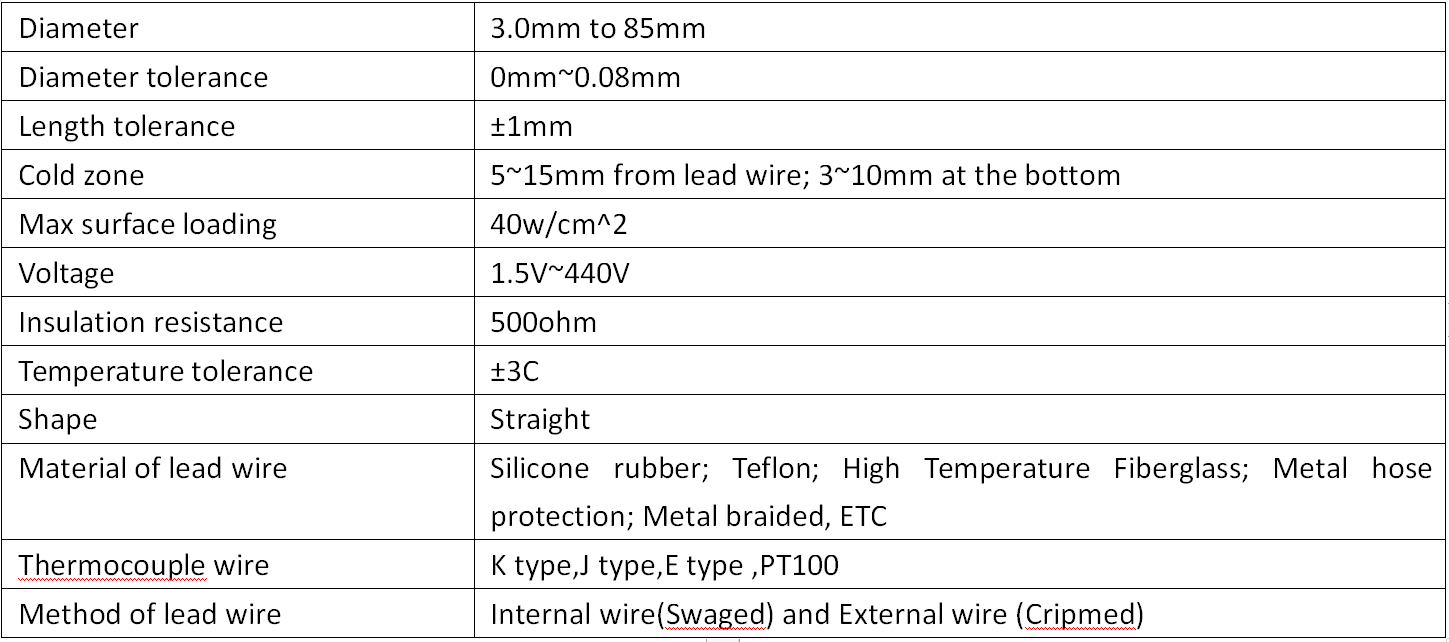

Order parameters of :

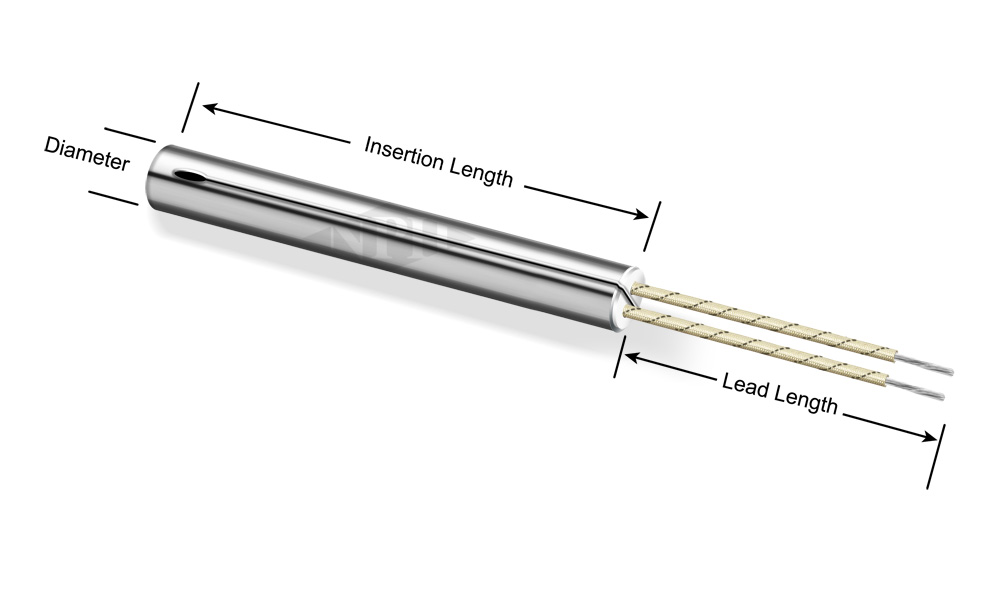

1.Diameter of pipe;

2.Length of pipe;

3.Voltage/Wattage;

4.Working temperature/Working environment

5.Method of lead wire

-

-

Which fittings can on Straight type Cartridge Heater ?

All products are using SUS304 or SUS321 seamless stainless steel pipe, MOG holder and MGO head with high temperature 1800C,99% MGO rod,overseas high temperature MGO powder, Cr20Ni80 resistance wire ,Ni-Mn lead wire and Silicone Rubber wire .It suits for mold heating . Large-scele production with competitive price,Good-look appearance of the product and excellent quality .

Laiyuan advantage of Cartridge Heater:

Order Parameters Of :

1.Diameter of pipe;

2.Length of pipe;

3.Voltage/Wattage;

4.Working temperature/Working environment

5.Method of lead wire

- Screw/Threaded

- Stainless steel chip

- Fin

- Flange

1. We make high quality cartridge heaters according to clients’ sample or drawing ;

2. We can make the most hard products according to clients’ drawings,the max surface load can be 40w/cm2

3. We can design the mold hole diameter hole distance, heating power etc according to clients’ mold and make the high quality cartridge heaters and customers’ mold .

4. Solve the heating imbalance problem specially for big mold,circle-roller and long packing cutter. We can make the cartridge heaters for these products which temperature tolerance within +/-3C.

5. Improve cartridge heater uselife by optimization design and reduce the energy consumption .

-

Split Sheath Cartridge Heaters:

Split Sheath Cartridge heaters are most frequently used for heating metal parts by insertion into drilled holes. The SST Split Sheath industrial heater is designed especially for platen, die or mold commercial heating applications where the holes are poorly drilled or worn through age. Independent expansion of each section of the SST when energized, creates intimate contact with the wall of the hole.

Features of Split Sheath Cartridge Heater:

1. Split Sheath design

2. Improved conductive heater

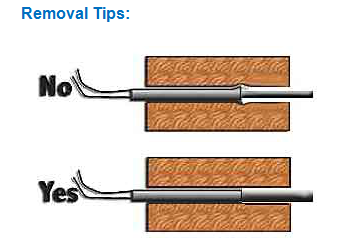

3. Easily inserted and removed from long holes

4. SUS304,SUS316,SUS310S Sheath for long life at extreme temperatures

5. Compacted to maximum density for excellent element to sheath heat transfer and dielectric strength

6 .3/8 - 1 Inch Diameter

7. 5 - 60 Inch Lengths

8. Sheath Temperatures up to 1600°F (871°C)

Applications of Split Sheath Cartridge Heater :

1. Platens

2. Presses

3. Dies

4. Molds

-

Our advanced swaged, square cartridge heaters combine the utility of a square configuration with the high watt density capabilities of swaged construction. Total commitment to engineering excellence is reflected in our successful efforts to improve heater performance and production efficiency. The results obtained clearly establish “MAXPAK” as the most consistent, reliable and economical cartridge heater on the market.

Laiyuan extended range of imperial square cartridge cross sectional dimensions was established to provide our customers with a full service source for virtually any square cartridge cross section required. A wide assortment of lead and seal options, construction variations and mounting options ensures compatibility with both new and existing heating applications.

Features of Square Cartridge Heater:

1. Size: 4*4mm,5*5mm,6*6mm,7*7mm,8*8m, max is 20*20mm

2. Mini Length: 1 1/4”

3. Voltage: 24V~380V

4. Lead wire: High Temperature Wire ,Teflon Wire,Metal Braided Wire

Application of Square Cartridge Heater:

1. Runnerless Injection Mold Heaters

2. Thermoset Mold Platen Heaters

3. High Performance Heaters

4. High Wattage Immersion Heaters

-

-

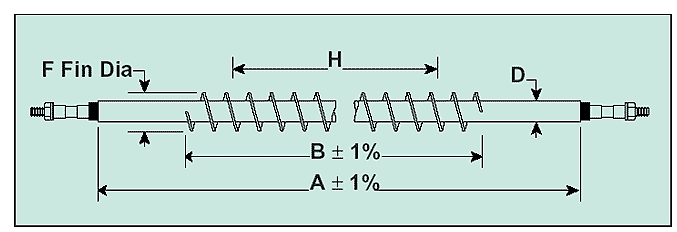

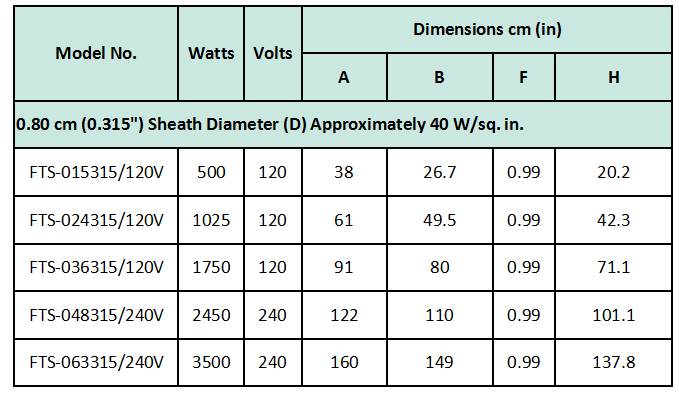

Description of Finned Tubular Air Heater :

Finned tubular air heating elements are constructed like basic tubular elements with the addition of continuous spiral fins, 4-5 per inch permanently furnace brazed to the sheath.Fins greatly increase surface area and permit faster hear transfer to air, resulting in lower surface element temperatures.

Features of Finned Tubular Air Heater :

Applications Of Finned Air Tubular Heater:

Maximum Sheath Temp. 455°C (850°F)

Fins for Fast Heat Transfer

100 to 5000 Watts

120 and 240 Vac Applications

Shape :Straight type,U type,W type,Round type etc

Drying

Heat Treating

Annealing

Load Banks

Curing

-

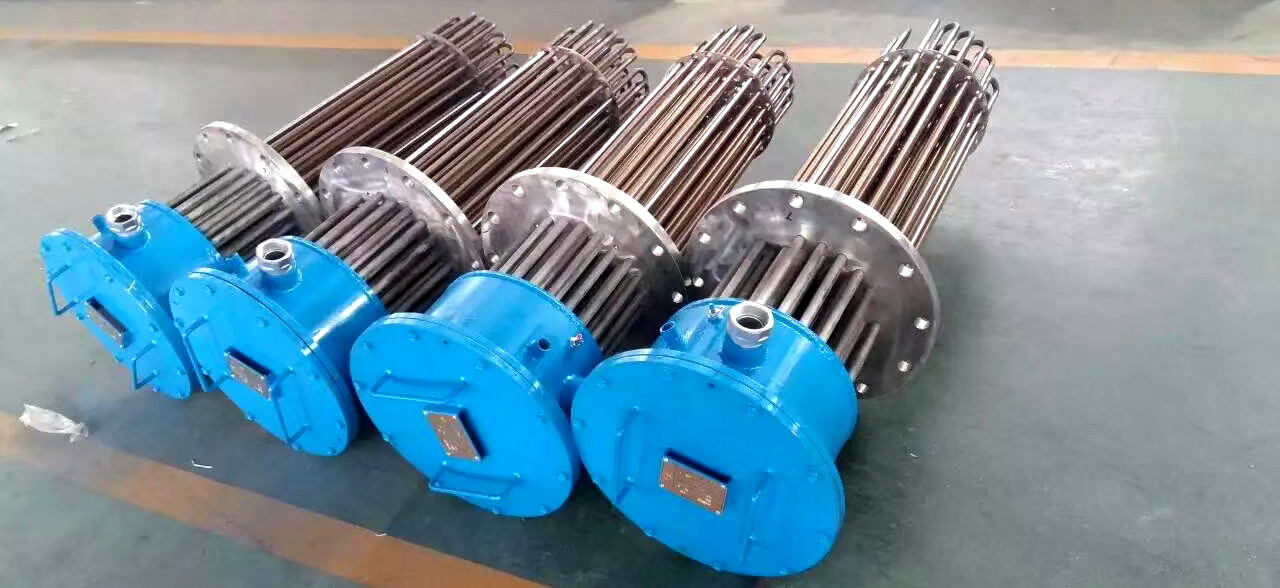

Laiyuan plate flanged heaters are easy to install and maintain. These flanged heater products are designed for heating heat transfer fluids, medium and lightweight oils and water in tanks and pressure vessels. Plate flanged heaters are ideal for applications requiring low to medium wattage requirements.

1. Direct replacement for many OEM mold temperature control units provides a single-source supplier for many OEM applications

2. ANSI compatible 1,1.5,2,2.5 inch and round type ,square type,Triangular type flange for appropriate heater size to application fit

3. Standard ,general purpose,or moisture resistant terminal enclosure to easily control access to wiring

Laiyuan plate flanged heaters are easy to install and maintain. These flanged heater products are designed for heating heat transfer fluids, medium and lightweight oils and water in tanks and pressure vessels. Plate flanged heaters are ideal for applications requiring low to medium wattage requirements.

Features & Benefits :

-

Industrial Heating Systems builds Immersion Heaters with PTFE Coating for Plating Tanks - PTFE stands for Polytetrafluoroethylene. This chemical resistant “plastic” has a maximum operating temperature of 430°- 450° F. So exposing it out of solution will have a failing condition on the heater. Thermal fuses that are popular nowadays, melt the PTFE layer, and produce enough heat to open the fuse circuit - by that time the heater needs to be replaced.

Industrial Heating System use liquid level probes that monitor the solution and turn the heater off prior to exposing it to open air.

Immersion heaters with PTFE coating are usually rated with 8 WSI (watts per square inch), so more heating elements are needed to attain the wattage output of a similar stainless or titanium heater. PTFE coated immersion heaters are used in metal finishing tanks with Hydrofluoric acids content of less than 9% by volume.

It doesn’t matter what chemical solution you put our PTFE heaters in, as long as it’s less than 200F, less than 2” from the top and has a pH of 0 to 13.

PTFE heaters can be used in any chemistry to 190°F but must have at least a 2” “no liquid zone” from the bottom of the junction box. Having the chemical solution closer to the top generates more steam and harmful vapors.

-

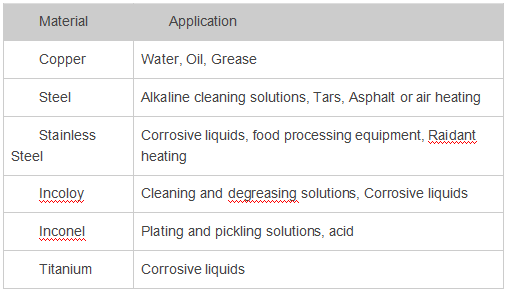

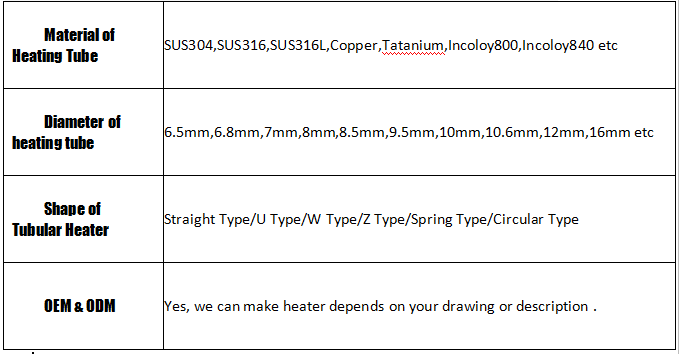

Tubular heating elements from Laiyuan are the most versatile and the best-suited industrial heating solution for a large number of applications. Tubular elements from Laiyuan are factory-configured to almost any shape or size.

Custom bending diameters can be made upon request and we can manufacture a variety of industrial heating solutions such as flanged tubular heaters. Tubular heaters are typically made using steel, stainless steel, Incoloy, inconel or titanium alloys. Tubular elements are often regarded as the foundation of all heating elements. These heating elements have a strong outer sheath to help protect the process heater from physical stress and uses high quality alloys to allow efficient heat transfer from resistance coil to your heating medium.

Different material of Tubular Heater in different working enviroment :

Features of Tubular Heater what Laiyuan have :

-

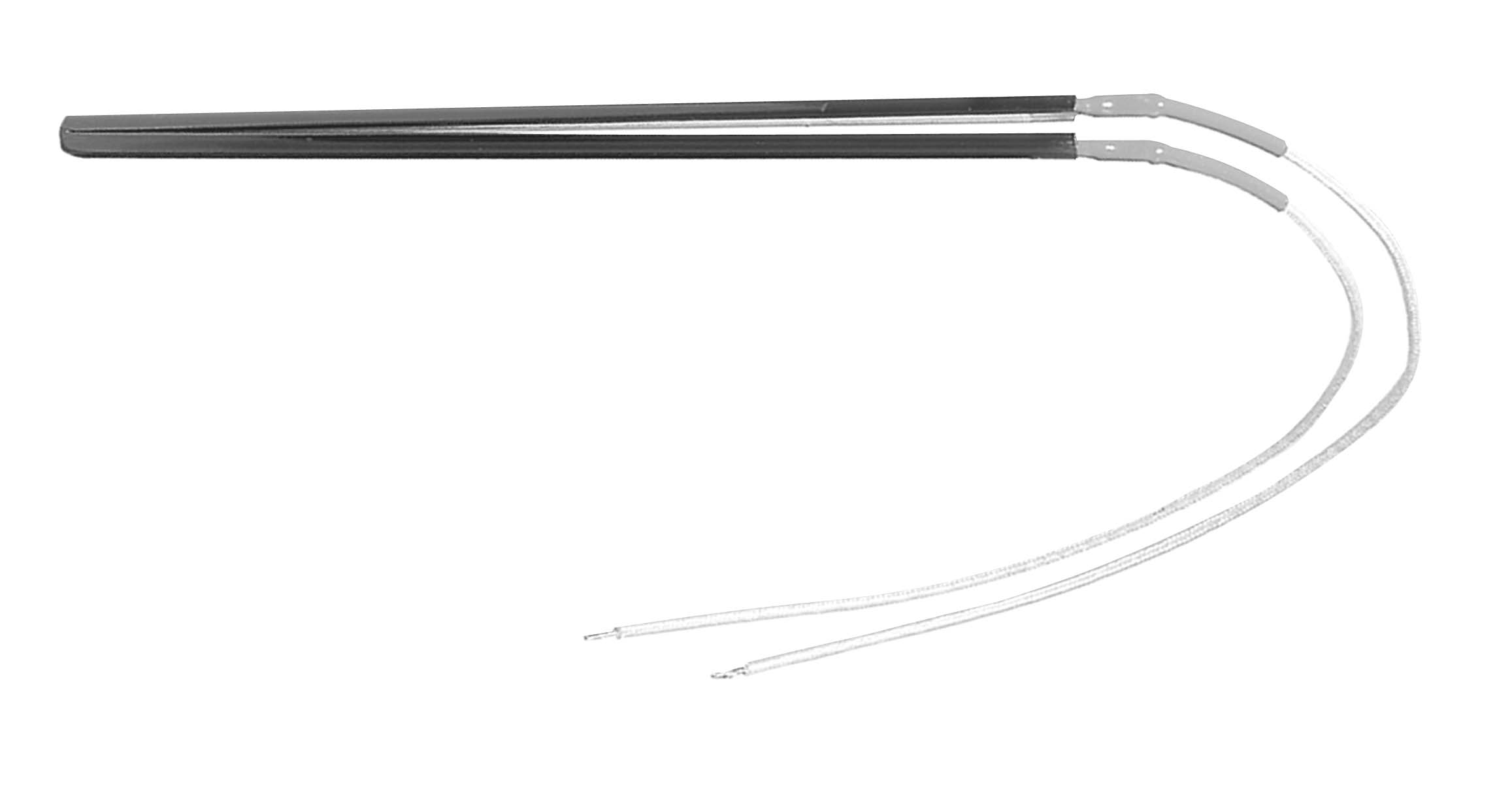

The Flexible heater which can be manually bent in all three dimensions. Easiest handling, simple assembly, optimal thermal features and the simple storage (the flexible heater is supplied in straight condition with numerous lengths from stock) are outstanding product arguments.

Towards the traditional heating the three dimensional bending of the makes high flexibility possible for engineers.

Features of Flexible Tubular Heater :

●Easy installation with a uniform finish

●Can be formed by hand

●Stored in a straight condition to save storage space

●No special installation tools required

●Patented technology ensures industry leading heat transfer

●Up to 75% sheath contact with round and square heaters when recommended groove geometry is followed

● Rapid heat-up times

● Minimal temperature difference between heater sheath and heated tool

● 3-dimensional groove geometry possible

●Industry’s smallest bending radius

● Flexibility enables heat to be located where it is needed; an improvement over rigid cartridge heaters

● Reduced energy costs: tool mass can be reduced

Technical key features:

1. Sheath material: stainless steel

2. Sheath temperature of heating element: Max. 600 °C / 1138 °F

3. Standard connection voltage: 230 V

4. High voltage test: 1000 V AC

5. Insulation resistance: ≥ 5 MΩ at 500 V DC

6. Leakage current: < 0.5 mA at 253 V AC

7. Wattage tolerance:± 10%

8. Length tolerance:± 1.5%

Six kinds Flexible Tubular Heater and Diameter as below :

1. Round Type

Material: Copper and Stainless Steel

Diameter: Φ6、Φ6.5、Φ7、Φ8、Φ10

Length:300~2000mm

Cold length of both end: 30±5mm

2. Metal Braided Type

Material: Stainless Steel

Diameter: Φ6.5、Φ7、Φ7.5、Φ8、Φ8.5、Φ10

Length:300~2000mm

Cold length of both end: 30±5mm

3. Groove Type

Material: Stainless Steel

Diameter: Φ6、Φ8、Φ10

Length:300~2000mm

Cold length of both end: 30±5mm

4. Flat Groove Type

Material: Stainless Steel

Diameter: Φ8、Φ8.5、Φ10

Length:300~2000mm

Cold length of both end: 30±5mm

5. Square Type

Material: Copper and Stainless Steel

Diameter: 6*6,7*7,8*8

Length:300~2000mm

Cold length of both end: 30±5mm

6. Metal Braided Square Type

Material: Copper and Stainless Steel

Diameter: 6*6,7*7,8*8

Length:300~2000mm

Cold length of both end: 30±5mm

Yancheng Laiyuan Electric Equipment Co., Ltd. 苏ICP备15027822号 Copyright © 2017, china-laiyuan.com Inc. All Rights Reserved

Pre-sales Advisory Hotline

+86-15851048592

Professional technical consultation

Comprehensive product interpretation

Customer case sharing

Wechat/ Hotline: